Ultrasonic AIRSCAN

Why and when are we using an ultrasonic Airscan?

Scanning large panels and products with ultrasound is often done with conventional ultrasonic testing under water ( or by using jet probes / squirters if the complete product cannot be submersed) , to produce a so called C-scan. C-scan comes originally from Contact scan ( really the old days), later with better electronics it became Contrast scan where grey tone plots were produced, but since better computer came available we called it Color scan. Obviously all with the same purpose to find anomalities in the products, such as delaminations, cracks, inclusions and any other parameter which influence the transmission of ultrasound through the material.

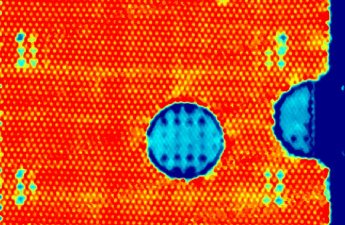

Basically it is the signal level (amplitude) which is monitored and plotted against the X/Y position on the product. Any variation in signal amplitude caused by a changing parameter in the material can become visible by changing colours in the scan. The result is a c-scan as below example.

Some products however cannot be wetted such as critical composite materials, of which a lot is used in the aerospace and space industry. Many of these products are manufactured in a cleanroom and contact with water can be a big problem in the manufacturing process. However, it is not only Aerospace. There are many materials in construction works, automotive industry which require quality testing.

It is a wide open market for various applications, although not all applications justify relatively high cost to inspect them.

Ceramics, foam product, paper based sheets etc are all potential for Airscanning.

C-scan of honey comb panel made with ITE Airscan

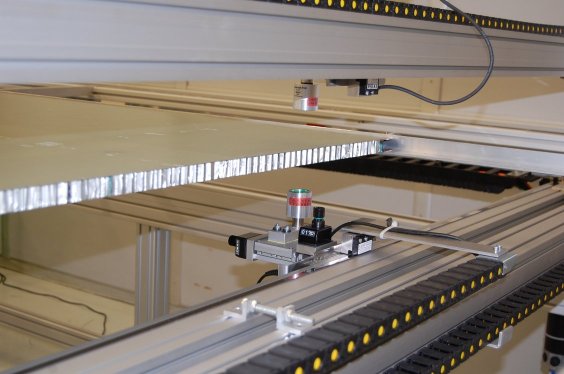

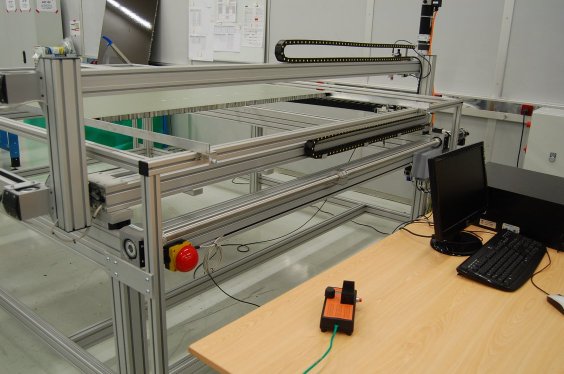

All ultrasonic scan systems built by Inspection Technology Europe BV meet the

recent European directives of mechanical and electrical safety and

electromagnetic compatibility.

The only practical way is using one transmitter and a receiver probe at the opposite side of the product. Sometimes it is possible to work from the same side with a certain distance between the probes. For this reason of using two opposite probest, airscanning is mostly limited to flat panels

Ultrasonic frequencies from as low as 50 KHz to 1 MHz can be used, depending on the application. For most composite materials and honey comb products frequencies between 100 KHz and 400 KHZ seem most practical.

High sensitive airscan testing requires very high gain for the ultrasonic circuit often in conflict with electrical noise from the mtor drivers. Special developed low noise motor drivers for these and other C-scan systems guaranty absolute noise free testresults up to maximum gain levels.