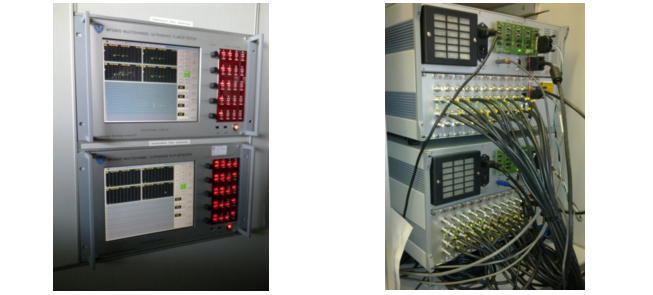

The MFD900 system is the powerful base for OCTG pipe inspection. A combination of parallel and multiplexed channels, combined with a smart pulse delay for each individual channel, allows for a very efficient pulse tuning to reach the highest possible inspection speed.

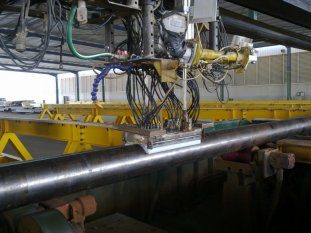

The MFD900 system has been optimized as well for this industry where the highest performance in speed, accuracy and reproducibility is required for long periods of continuous use. Testing the numerous pipes for ID and OD ( inner and outer surface) defects in transverse, longitudinal and sometime oblique direction as well as testing for delamination and wall thickness in a continuous reliable way requires a robust and reliable mechanical handling system and ultrasonic equipment.

Inspection Technology Europe BV can supply the ultrasonic equipment quickly and assist you with the integration in the plant. Our respected customer Eurotechnology in the Middle East can supply the mechanical hardware as well as the EMI testing section.

Stack of two MFD900 ultrasonic systems in operation

Servicing the MFD900 system is easy and quick. Changing a dual channel pulser receiver module and system controller can be done in the field in just a couple of minutes by a local operator. All other hardware inside the ultrasonic instrument is built up from standard components as much as possible.

For instance , power supply modules are of a type that can be obtained in most parts of the world should one fail. Even the compact central PC inside the system can be exchanged in perhaps 10 minutes. Even more, if there is no direct replacement PC one can use a standard external PC with some extension cables to take over the PC function till the original PC can be put back.

OCTG ultrasonic pipe inspection