Non contact ultrasonic testing is also called Airscan . Reason is that the ultrasonic sound does not require a couplant such as water to transmit the sound pulser through the material but it transmits the sound pulses through air.

Important to realize is that this method only works well in the so called Through Transmission mode.

One transducer is positioned at each side of the material to be tested.

Typical applications are testing sheet material for internal delamiations due to poor bonding or damages. This could be composite material, plywood, parquest planks etcetera.

Inspection Technology has introduced a complete ready to use system for testing parquet planks with a testing high speed, depending on the defect sizes.

Defects as small as 1 cm are typical for 20 meters / minute.

If needed and by using sharper focussed transducers defects as small as 1 mm can be detected.

Set up and operation is extremely easy and requires no ultrasonic knowledge and experience.

It is very operator friendly.

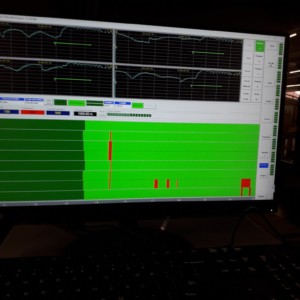

Test station with defect paint marker and display to view the results

Close up of the 8 track test results. Red shows delaminations

Close up of the 8 track test results. Red shows delaminations

complete system with feeder- and exit table

complete system with feeder- and exit table